In fast-paced settings like logistics hubs, F&B facilities, and manufacturing plants, forklifts and trucks constantly navigate tight spaces, increasing the risk of collisions.

These incidents endanger employees and can damage costly equipment and infrastructure.

MPM Plastics Protection from Italy offers a durable solution designed to absorb and diffuse impact forces, ensuring safer operations and reducing costly repairs.

Why Industrial Collision Protection Matters

- Employee Safety

High-speed or miscalculated maneuvers with forklifts can lead to collisions that endanger operators and bystanders. Implementing forklift impact protection solutions helps reduce injuries and downtime, keeping your workforce healthy and productive. - Asset Preservation

Even minor accidents can result in significant repair or replacement costs for damaged infrastructure, such as racks, loading docks, and facility walls. Industrial collision protection systems help shield these key assets, reducing costly interruptions to your operations. - Regulatory Compliance

In Singapore, workplace safety and health regulations emphasize the prevention of industrial accidents. Properly installed MHE impact protection systems play a vital role in meeting these standards, showing a commitment to both safety and legal compliance.

_______________________________________________________________________________________________________________________________

MPM Plastics Protection: A Game-Changer in Collision Safety

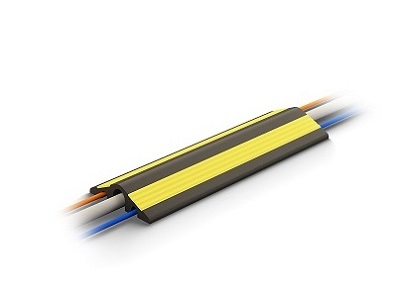

Unlike traditional metal or concrete barriers, MPM’s plastic-based solutions offer a higher degree of flexibility, elasticity, and durability—all crucial for industrial collision protection.

- Shock-Absorbing Design

MPM barriers are engineered to absorb and disperse the impact force, minimizing the damage to both the barrier and the colliding vehicle. This results in fewer costly repairs and less downtime. - Corrosion and Chemical Resistance

Singapore’s humid environment can lead to rust and corrosion on metal barriers. MPM’s plastic barriers are rust-free and resistant to industrial chemicals, ensuring long-term performance even in harsh conditions. - Reduced Maintenance

Thanks to their robust construction and ability to regain shape post-impact, MPM plastic barriers require minimal to no repairs. This contrasts starkly with metal barriers that often need repainting or replacement after repeated collisions.

Easy Integration

MPM offers a range of modular designs that can be tailored to different facility layouts. Whether you need forklift impact protection near racks or lorry buffer zones at loading docks, their solutions adapt to fit your specific requirements.

_______________________________________________________________________________________________________________________________

Applications Across Diverse Sectors

- Logistics and Warehousing

In these fast-moving environments, forklifts are constantly shuttling goods between storage racks and loading bays. MPM Plastics Protection helps prevent collisions that can damage racking systems, support columns, and warehouse structures. - Food & Beverage (F&B)

F&B facilities handle sensitive products that require stringent safety standards. MPM’s chemical-resistant and non-corrosive barriers ensure long-lasting protection, preserving both product quality and employee safety. - Manufacturing Plants

Heavy machinery, assembly lines, and frequent movement of raw materials make manufacturing plants prone to collisions. By installing industrial collision protection from MPM, factories can minimize operational disruptions and protect critical equipment.

_______________________________________________________________________________________________________________________________

Benefits for Singapore Businesses

- Enhanced Workplace Safety

A proactive collision protection system fosters a safety-first culture—an important factor in attracting and retaining a skilled workforce in Singapore’s competitive labor market. - Lower Total Cost of Ownership

With minimal maintenance and fewer repairs, MPM barriers help businesses save on long-term costs. They also reduce downtime, allowing companies to meet tight production and delivery deadlines. - Compliance and Reputation

Demonstrating a commitment to safety and regulatory compliance enhances your corporate image, giving you an edge in Singapore’s thriving industrial sector. - Customizable Solutions

MPM understands that every facility’s workflow is unique. Their flexible and adaptable designs can be custom-fitted to specific areas—whether it’s warehouse aisles, production lines, or loading docks.

_______________________________________________________________________________________________________________________________

Switch to MPM Plastics Protection: Safety Meets Productivity

In today’s fast-paced industries, robust collision protection is essential. MPM Plastics Protection offers advanced solutions for forklift, lorry, and MHE impact mitigation—helping businesses in Singapore protect their workforce, infrastructure, and bottom line.

Ready to enhance safety and reduce collision risks? Join the growing number of companies moving away from outdated systems and adopting MPM’s reliable, low-maintenance protection. Contact us to learn more!