In modern industrial and commercial settings, impact collision protection is crucial for maintaining a safe and efficient workplace. Protecting assets such as buildings, equipment, and personnel against accidental impacts from Material Handling Equipment (MHE) or vehicles can help prevent costly damages, minimize downtime, and enhance safety protocols. This guide aims to provide business owners, building managers, and facility managers with insights into why impact protection is essential, how it works, and what types of solutions are best suited for various applications.

The Importance of Impact Collision Protection in Industrial Settings

Impact collision protection solutions are essential investments for facilities with high traffic from vehicles or MHE. These barriers, bollards, guard rails, and other protective measures serve several purposes, including:

- Safeguarding Assets: Preventing damage to buildings and equipment reduces maintenance costs.

- Ensuring Employee Safety: Protecting people from potential collisions improves overall workplace safety.

- Compliance with Safety Standards: Many industries are required to adhere to safety standards like PAS13, EN15629, and EN15512 to maintain safe working environments.

Types of Impact Collision Protection Solutions

1. Safety Barriers Safety barriers are designed to absorb and deflect impacts, providing robust protection for structures and personnel. These barriers come in various forms, including:

- Pedestrian Safety Railing: Designed to separate pedestrian pathways from vehicle traffic, these railings protect people from accidental collisions.

- Warehouse Guard Rails: Commonly used to protect shelving units and storage areas from forklift impacts.

2. Bollards Bollards are heavy-duty posts that provide both visual and physical barriers to prevent vehicles from colliding with structures or entering restricted zones. Applications include:

- Parking Lot and Carpark Protection: Bollards are often used to protect entrances, exits, and key pedestrian areas in parking facilities.

- Loading Bay Protection: Ideal for areas where trucks are loading and unloading goods, helping to guide vehicle movement and prevent accidental collisions.

.jpg)

3. Crash Barriers These barriers are commonly installed at critical points where high-speed impacts are more likely, such as along loading bays or entrances to restricted zones.

4. Height Limit Warning Bars For facilities with low overhead clearance, height limit warning bars serve as a pre-emptive measure to prevent tall vehicles from damaging overhead structures. These bars are especially important in areas like underground parking or loading bays where vertical clearance is limited.

Key Standards and Regulations

The significance of adhering to safety standards cannot be overstated, especially for facilities handling heavy machinery and high foot traffic. Important standards to consider include:

- PAS13: Offers guidance for the design and installation of safety barriers in industrial environments.

- EN15629, EN15512, and EN15635: Provide guidelines on storage equipment safety, helping to prevent injuries and equipment damage.

Compliance with these standards ensures that safety equipment meets required specifications, reducing liability and enhancing safety.

Choosing the Right Protection Solutions

Selecting the correct type of impact protection for your facility depends on several factors, including traffic volume, type of assets to protect, and the nature of activities performed on-site. Here are some considerations:

- Facility Layout Understanding the layout of your facility can help you identify high-risk areas where collisions are more likely to occur. Placing bollards, guard rails, and barriers in these spots can provide targeted protection.

- Type of MHE and Vehicle Traffic Facilities with forklifts, trucks, and other heavy equipment should prioritize heavy-duty barriers, while facilities with lighter vehicle traffic might benefit from standard safety rails and bollards.

Specific Vulnerable Areas Identifying vulnerable areas, such as loading bays, storage sections, and pedestrian walkways, can help in choosing suitable protective measures for each section.

The ROI of Impact Collision Protection Solutions

Implementing impact protection solutions offers tangible benefits that outweigh initial investment costs:

- Reduced Maintenance and Repair Costs: Impact protection reduces the likelihood of structural damage, minimizing costly repairs.

- Improved Safety Record: Enhances the reputation of the business as a safe place to work, potentially lowering insurance premiums and increasing staff retention.

- Compliance with Regulations: Avoids potential fines and penalties for non-compliance with safety regulations.

Top Products for Impact Protection

- Barrier Systems for Warehouses Designed to withstand impacts from forklifts and other MHE, these barriers help keep storage racks and walls intact.

- Heavy-Duty Bollards Ideal for loading bays and car parks, these bollards provide excellent resistance to vehicle impacts.

Pedestrian Safety Rails Essential for facilities with both vehicular and foot traffic, these rails help protect employees while allowing for smooth vehicle movement.

Investing in impact collision protection is an essential step toward creating a safe and efficient workplace. By carefully assessing your facility’s layout, the type of vehicle traffic, and high-risk areas, you can select the right solutions to protect your assets, employees, and operational integrity. With proper impact protection in place, facilities can expect to see reduced costs associated with repairs, improved safety for staff, and compliance with industry regulations.

Get Started

Ready to protect your facility and ensure workplace safety? Explore our range of impact collision protection solutions and find the perfect fit for your business needs today!

| Description | Product |

|---|---|

|

Tech Solutions |

|

Rack Protections |

|

Bollard |

|

Guard Rails |

|

Cold Line |

|

Traffic Barrier |

|

Pedestrian Safety Barriers |

|

Safety Gates |

|

Column Protections |

|

Industrial Door Protection |

|

Warning Bar |

|

Truck Line |

|

Corner Protections |

|

Loading Bays Protections |

|

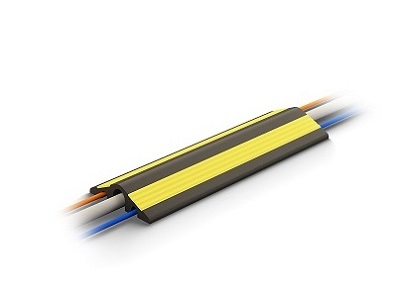

Cable Cover |

|

Wheel Stop |